Installation of switchgear for a cloud data center

What happens during this installation?

In June 2022, together with our partners from STS Group – Dussmann and Zauner Group, Montron GmbH began installing switchgear at the Schwechat location. The entire project coordination was taken over by Montron GmbH. It was crucial to organize and coordinate the various participating companies in advance and on-site. In total, more than 60 systems (100kg – 42,000kg) will be lifted and installed in this project. The installed systems are an essential part of a well-known software company’s cloud data center.

The systems, which can be up to 18m long and 4m wide, must be placed with an accuracy of +-0.5cm.

Lifting work of insertion

What is the biggest challenge during the installation?

Operations of this nature must always comply with applicable safety standards. On a busy construction site with a total of 300 people in a confined space, the lift of the 18m-long systems is particularly challenging. No one other than the Montron coordinator’s team should be within the entire lifting radius to ensure no one is endangered. For many systems, special feet had to be mounted before the final placement. The system was lifted on a low-loader so that the system’s base feet could be installed. This required precise teamwork.

HSSE (Health, Safety, Security, Environment) is an important part of our company philosophy. The goal of our health, safety, and environmental management is to continually reduce risks. Appropriate rules and careful documentation ensure the highest level of safety for people, facilities, and the environment. Our TÜV certifications are part of our HSSE strategy. Which ensure the quality of our installations and provide security for both you and your customers.

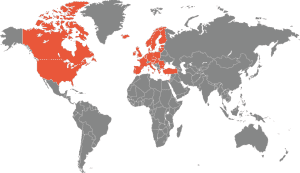

The unrestricted SCC** (Safety Certificate for Contractors). Especially on an international construction site like this, it is always important for us to implement HSSE guidelines, especially during such installations.

Why is Montron GmbH the right company for installations?

With our long-standing partners, we are always ready to fulfill any order. Often, it requires creative solutions from our many experts to meet customer needs. The success and our way of handling international projects to the best of our ability prove us right in what we do.

Our highly trained and experienced staff ensures a short relocation time and reduced production downtime. We take care of machine transport, which, if necessary, can be organized and carried out as a special or heavy transport. At the destination, we perform machine installation and assembly according to your layout plan properly and precisely. By combining machine dismantling, machine transport, and machine assembly in one package, you save valuable time and money. Our experienced staff is already familiar with most machine and system configurations, eliminating the need for them to familiarize themselves with the assembly process. This eliminates coordination time between multiple companies and waiting time for external technicians.

Preparing the unloading area of switchgear

OUR SERVICES OVERVIEW

- Project scope assessment

- Cost estimation

- Project workflow planning

- Professional installation with documentation

- Machine transport

- Placement at the new location

- Reassembly and setup of the machines

- Commissioning with functional testing

MORE EXCITING ARTICLES AND PROJECTS FROM MONTRON CAN BE FOUND HERE

- Machine installation assembly

- Advertising assembly

- Montron – Installations with large equipment

- Billa Plus conversion with 15 installation teams

- MoFix – The craftsmen with the best ratings

- Montron relocates cleanroom production equipment from Ringana

- Installation of over 5000 m² of noise protection

- HTBLA Zeltweg – Relocation of workshop machinery

- Summer is coming! Over 450 Napoleon grills assembled

- …..

👉🏼CAREER AT MONTRON – APPLY NOW! 👈🏼

Our employees are our most valuable asset. Through their skills, commitment, and satisfaction, we have been able to write a success story in Austria for over 25 years.

As one of the leading assembly companies, we are always looking for new talents who want to shape the future with us. We offer our employees a secure working environment, exciting fields of work, and the opportunity to further develop their knowledge and skills.